Blake Wiggins and Peter Manos

As part of its work with numerous electric, gas and water utilities, Indus International has developed an integration framework and functional capabilities to support the use of Geographical Information System (GIS) capabilities across a wide range of utility functions, in coordination with our Enterprise Asset Management (EAM) solution.

Many utilities share a vision of using GIS as a central function. Experience has shown that optimal integration to Enterprise Asset Management (EAM) solutions, along with electronic document management systems (EDMS), helps maximize utility return on GIS investments. EAM / GIS integration enables engineering, field, and customer-facing personnel to utilize links which optimize their effectiveness, from design engineering and project planning, to linkage of field work and customer service activities. Along with EDMS, an EAM/GIS solution maximizes the value of information to all utility personnel by preventing “silo-ing” of information, and maintains data integrity, from work request to close-out.

1. Background EnterpriseAsset Management

Enterprise Asset Management (EAM) solutions form the core of a utility’s operating environment, in combination with GIS, CIS and outage management and SCADA systems. The ideal EAM system should provide a scalable comprehensive solution to cover all Operations and Maintenance (O&M) activities associated with utility assets. EAM systems go beyond traditional Computerized Maintenance Management Systems (CMMS) to encompass a wider range of functions across the enterprise. This ranges from maintaining, designing and constructing new infrastructure, to planning, executing, and tracking all O&M activities. The ideal EAM solution should combine predictive, preventive, condition-based, and reliability-centered maintenance approaches, while optimizing the MRO (Maintenance, Repair and Operations) supply chain.

Typical components of an EAM system are shown below:

| SAFETY & COMPLIANCE Personnel & Qualifications Data Materials Safety Data Sheets Equipment Tag Out |

WORK MANAGEMENT Work Management Document Management Labor Entry & Reporting Project Management Action Tracking Design Engineering |

MATERIALS & PROCUREMENT Inventory & Warehouse Management Purchasing Contract Management |

Key functions of the EAM system involve the ability to receive service and work requests, schedule work, track labor (internal and external), equipment and materials and forecast the usage of these resources. The system automates the entire safety and compliance process, including personnel training and certification; response to incidents; quality assurance of equipment and facilities; and manages such critical data as maintenance work history, preventive programs, and planned and scheduled activities that provide complete audited reporting capability. Ideally the EAM solution should also include comprehensive functionality in e-procurement, mobile computing and electronic document management systems (EDMS), imaging, electronic forms, and workflow.

Regarding this last element, an important aspect of the relationship between EAM and GIS concerns optimally reengineering work flows in coordination with the utilization of integrated technologies. It is vital for utilities to have systems which ensure the best possible data sharing between all personnel involved in delivering services.

The coordination of GIS with an integrated EDMS capability is a key element in ensuring all business processes are designed to enable optimal utility operations. Organizations which have analyzed the use of GIS have found dozens if not hundreds of different workflows, many of which need more coordination so that information is accessible everywhere it is needed, and information not entered redundantly or “dead-ended” in a workflow that terminates in a paper-based process.

This requires that an enterprise-wide view take priority in determining the architecture of the system. Only then can the solution be implemented optimally at a departmental level.

1.1 The Importance of Workflow and Electronic Document Management Systems

In order to take the maximal advantages afforded by the integrations between GIS and EAM discussed here, the benefits of an integrated Workflow and Electronic Document Management System (EDMS) need to be considered. The optimal EDMS system should provide seamless and easily-built workflows for approval processes, and a depth of integration and historical access to documents and prior processes. There are distinct advantages to a well-architected EDMS system, versus the numerous workflow and document management solutions which rely upon OLE links to access documents. In the best EDMS systems, links to documents are not broken when security rules on the system or changed, or when the file names or locations of the documents are changed. Systems which rely on OLE links do not guarantee the level of system integrity that ensures users are looking at the latest version of a document. In addition in the absence of this level of system integrity, the user may lose the ability to view prior versions of documents (e.g. for audit purposes) so that the document version which was in use during the time in question is available.

2.0 Typical areas for EAM integration to GIS

The main areas to consider regarding EAM integration to GIS solutions include:

1. Design / new construction

2. Service request / outage management

3. Maintenance - GIS initiated work

4. Facilities / Equipment Database

Work activities can be initiated either in the EAM system or the GIS. Consistent representation of assets to all users is a significant benefit of the integration of these systems. In addition the incorporation of mobile computing solutions touches upon many aspects of the GIS / EAM integration.

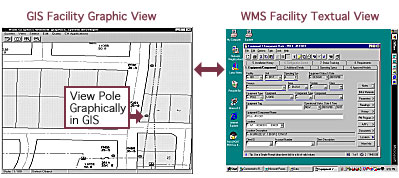

In all cases, there is value for users in the linkage from the GIS system’s graphical view and the EAM system’s textual view of assets. Below a review of these 4 areas is provided, followed by discussion of Enterprise Application Integration (EAI) considerations and the business benefits of this solution.

1.1 Graphical GIS View links to textual work management view

2.1 Aspects of the design process and model of installed equipment

One of the most expensive resources among utility personnel is the engineering designer’s time. An optimal integration of the GIS solution with the EAM system’s design tools ensures the highest efficiency of design processes. In addition, in order to effectively manage designer’s workloads, integration of the solution with a resource optimization tool is essential.

The need for a design is registered in the EAM system, but typically the design alternatives are developed in the GIS system. These design alternatives are transferred back to the EAM system for full cost estimation and authorization work. After approval, the design is converted to work order tasks, and the tasks are tracked through to completion. A general diagram of the process is shown below.

2.1 Diagram of design workflows between EAM and GIS

The data shared between the EAM and GIS system in this workflow consists of:

| Asset As-Built Information |

Material Information |

| Compatible Units (CUs) |

Status of Work Order Tasks |

| CU Groups “Macro CUs” |

Status of Construction Work |

| Customer Information |

Location Information |

| Designs |

Material Information |

| Design Versions |

Status of Work Order Tasks |

| Location Information |

Status of Construction Work Orders |

Compatible Unit data is the main component of GIS design alternatives. Compatible unit groups, and compatible units, are typically related to symbols specified within the design alternative. The GIS integration to EAM enables the transfer of this data so that it is available during the design process. Large projects consisting of a hierarchy of work orders can form a “Macro CU” or set of interrelated Compatible Units in the EAM system.

Reference data provided to the GIS system includes compatible unit and equipment ID data. The compatible unit data is employed during the development of GIS design alternatives. After construction has been completed, the “as-built’ design is incorporated into GIS plant maps. Equipment ID data is then used to support maintenance activities. (This is covered in more detail in section 2.3 below).

2.2. Key Elements of Utility EAM / GIS Integration

Automation of this process is important for many reasons. Not only does it increase personnel effectiveness, it also enables the utility to ensure that new assets are promptly and accurately entered into the rate base according to all appropriate accounting rules. The EAM system should fully support the complexities involved in providing the utility’s ERP / financial system with detailed data for depreciation and capitalization of assets.

Utilities which rely on non-automated systems for this workflow have reported data entry backlogs in their Land Use, or Electric and Gas Divisions, up to and exceeding one year in length. Many utilities with non-automated systems report that they are incurring excessive clerical expenses in order to avoid backlogs. Obviously it is desirable to have an automated system to optimize this process.

Ideally the EAM system should also have a mobile computing solution. This can be used both in “real time” for service order or trouble ticket related work processes, but also in a “disconnected” mode which can enable designers to opt for “field design” work when appropriate. For example, instead of doing all their design work in the office, the field designer can go to the job site with a ruggidized laptop or other mobile device and record information which can then be used to complete the design. This can help prevent the need for changes to the design, since the designer can incorporate more detailed topographic or clearance information. For example by being in the field instead of relying on maps at the office, the designer can avoid placing a padmounted transformer in a gulley, or a pole too close to an obstruction.

Once a compatible unit is transferred through to the GIS, an estimate is generated for the components of the compatible unit. This estimate uses the base rate for resources and the average unit price for material. The system should support the high level of complexity that can occur for example due to the fact that utilities often have service territories across different states, with a variety of rules and may impose different requirements on the depreciation, amortization, or other accounting treatments involved.

Scheduling of field crews often requires the coordination of permits and isolation requests which are coordinated within the EAM system.

2.2 Service requests

Service requests are the opposite of design work from a data intensity point of view. Typically there are numerous service requests, each involving relatively low levels of information content, while in the case of design work, there are a small number of designs but each one has a very high information content. As a result the integration requirements dictate different supporting requirements from an architectural and throughput point of view.

However in the service request process, as in the design process, it is important for utility personnel to have GIS graphical and Work Management textual views of the work.

2.2 Service Request Process—GIS and Work Management views of work

To effectively schedule personnel and equipment, resource optimization capabilities are needed in order to support the service request process. The EAM solution should include an integrated resource leveling tool that balances and develops an optimal schedule. This tool should generate a schedule or set of schedule options based upon user defined rules and criteria, using both a constraint-based and value based optimization engine. Typically this engine complements, rather than replaces, the EAM system’s CPM and resource leveling tools which are employed for large projects (including integration to Primavera or MS Project).

This scheduling capability for the service request process needs to provide advanced crew/schedule planning, and should help improve customer satisfaction by meeting commitments and providing more accurate commitment windows. By providing a graphical capability to revise and re-schedule workloads, the job planner’s activities are optimized. response capabilities are to be supported by the system, along with support of Service Level Agreements.

2.3 Maintenance GIS Initiated Work

In this third workflow an engineer or planner will use the GIS system as the starting point for new maintenance work which has to be done.

While in the case of previously-discussed integrations the work was often initiated in the EAM system and data flowed to the GIS system, in this instance the flow is the other way. This highlights the importance of the open integration approach, with a two-way integration between GIS and EAM system.

In reviewing this workflow and the workflow in the first section on Design Engineering, we should note that not all facilities that have been designed and constructed qualify for maintenance tracking. In the next section we discuss the Installed Equipment List, which is a differentiator between equipment which requires maintenance tracking vs. equipment which does not need to be added to the maintenance database.

2.4 Facilities / Equipment Database

Facilities and equipment also need to be viewed in both the GIS and EAM systems for diverse purposes.

It often happens that the as-built construction is different from the original design. When a job is completed, if there is no difference between the as-built construction and the original design, then the as-built design is incorporated into the GIS plant maps. However if there are design changes during construction, the EAM system needs to be flexible to record the new design.

For this reason, part of the work order management system should include an Installed Equipment List. This list is maintained at the work order task level. During task completion, the Installed Equipment list is updated and applied to the EAM’s equipment data to reflect the action taken with the construction. When a work order task related to an external design is completed, the Installed Equipment List is transferred over to the GIS, thereby providing a graphical record of the assets affected by the construction.

3.0 EAI (

Utilities and software vendors recognize the value of an open integration approach. To this end Indusis collaborating with the IEC TC57 WG14 . This Working Group is dedicated to providing a set of agreed-upon standards for Distribution System interfaces.

Utilities benefit from this approach by being members of a community with a common baseline of integrated modules. The same integration is employed independently of which vendors supply which particular module. This standardization provides utilities with the maximal degree of choice regarding which vendors are supplying which components per the diagram below.

3.1 Architecture overview of IEC TC57 WG14 Distribution Interface Model

Consistent with the above model, Indus Internationals EAI approach, IndusConnect, takes a components-based approach to this functional solution, based upon standard, re-usable modules as integration vehicles. The goal is to ensure flexibility to adapt to emerging technologies and new software solutions. This enables utilities to select the best complementary products to meet their business requirements.

As the realities of existing utility legacy systems dictate, Indusand other vendors need to be amenable to a hybrid approach which combines open EAI architecture with the use of point-to-point APIs as needed, or which transitions from the older model to the new EAI model as required. In the long term the total cost of ownership for maintaining a system will be significantly lower with the EAI structure, since it allows for appropriate abstraction layers to ensure independence from third party system components. IndusConnect includes a Business Object Development tool which easily facilitates new data creation and modification of existing data, with re-usable modules as integration vehicles from the IndusConnect Business Objects Library.

4.0 Business benefits

Broadly speaking, the business benefits of optimal GIS / EAM integration can be broken into two categories: The improvement in personnel effectiveness, and the reduction in total cost of ownership engendered by the EAI approach.

Personnel effectiveness is increased in numerous ways:

1. Optimization of design engineer’s time

2. Access by all utility personnel to common data

3. Reduction in clerical costs associated with maintaining up-to-date asset models in EAM and GIS systems

4. Increased efficiency of field work due to integration of mobile, GIS, and Work Management

5. Optimal scheduling of work

a. Defined priorities

b. Most important customers

c. Due dates

d. Critical assets

e. ‘Windshield time’/travel distance minimized

f. Most cost-effective resource available used

g. Work criticality is escalated to meet rules set by ‘value’

Lower total cost of ownership is achieved:

1. Baseline software approach avoids costly customizations

2. Common data model lowers costs of maintaining systems

3. Leverage effort and lower risk by working on common functionality with utilities and vendors

4. Benefit from evolving marketplace of conforming applications

5. Open approach lowers efforts required to integrate legacy systems

Conclusion:

The question of whether the GIS or EAM system is at the “center” of Energy Delivery utility operations becomes moot when we recognize the shift embodied by the EAI approach. In reality there is no longer a “center”, since both the graphic GIS view and the textual EAM view are both linked via the middleware bus to a host of other mission-critical utility applications.

Authors Information:

Blake Wiggins

Director of Product Strategy

IndusInternational

(415) 904-4018

Blake Wiggins is the Director of Product Strategy, EAM Solutions, for Indus International and has over 10 years of multi-disciplinary experience with utilities, technology and process industries.

Peter Manos

Senior Sales Executive

IndusInternational

(770) 989-4088

Peter Manos has over 17 years of utility industry experience and has published numerous articles in the utility trade press.