|

Abstract

Geographic Information System (GIS) technology is quickly

becoming a critical component to develop and sustain asset management

for today's water utilities. Used as a spatial database, GIS can greatly

assist in various modeling applications through the development of automated

tools for constructing and maintaining reliable hydraulic network models

of water distribution systems. This paper presents a comprehensive GIS-based

decision support system, called H2OMAP Utility Suite, for use

in the effective planning and management of water distribution systems.

It links an advanced hydraulic network simulator with geospatial technology

and optimization theory to address every facet of network modeling and

asset management. Built with Esri MapObjects technology, the resulting

software will effortlessly read GIS data, extract necessary modeling information,

and automatically construct, skeletonize, load, calibrate, secure and

optimize a representative network model. It also makes it easy to run

and simulate various modeling conditions, identify optimal monitoring

stations, locate system deficiencies, and determine the most cost-effective

improvements for optimum performance. The optimization model uses an efficient

variation of the genetic algorithm for solving network model calibration,

field sampling design, pump scheduling, and network design and rehabilitation

problems in an optimal fashion. The integrated approach offers a virtual

geospatial environment to assist water industry executives and professionals

in formulating, evaluating and prioritizing facility management and infrastructure

security strategies.

Introduction

Computer simulation models of water distribution systems

represent the most effective and viable means for evaluating system response

to various management strategies. To be effective, these models require

extensive spatial and hydraulic infrastructure data readily available

from GIS. This information system format is unique in its ability to capture

and store facility data and spatial reference for asset management and

eventual hydraulic network model integration. It provides functions for

development and preparation of pertinent spatial information for input

to network models as well as functions to facilitate graphical output

display for evaluating results. Added visualization tools can be applied

using spatial and aspatial queries of model results to help identify correlation

between input parameters and model results. Therefore, the integration

of water distribution network models with GIS is a natural development

of hydraulic simulation tools complemented with the evolution and maturation

of relational database technology.

While many powerful water distribution modeling software exist, few are

currently integrated with a GIS platform. Engineers familiar with the

(CAD) environment have grown increasingly dependent on the hydraulic software's

usability, interface, and CAD-like features. Likewise, enterprise GIS

software has not been tailored, both in terms of price and functionality,

to serve the requirements of water distribution planning and analysis.

As such, software for the analysis of water distribution systems was normally

created in the CAD environment to receive acceptance from an engineering

community already familiar with AutoCAD for other civil applications.

No such software however, has been developed to integrate the water distribution

modeler's needs with the data and spatial reference abilities of GIS.

This paper presents a new perspective to water distribution planning and

management. It is a unique network analysis platform that addresses the

requirements of the modeling engineer while providing the functionality

of a GIS for consistent facility asset management1-2. The graphical interface

is developed using Esri's MapObjects geospatial technology and provides

an informative structured framework for database management and complete

network model construction, analysis, and result presentation.

Water utility engineers are responsible for ensuring the safe and efficient

supply of drinking water. The role of a GIS in the analysis of a distribution

system is to provide up-to-date and accurate data to be used in the engineering

analysis. For years, engineers have exported data from GIS data sets to

third party software for analysis and design of water distribution systems.

Applications and functionalities such as energy and fire flow analysis

with the ability to model different demand and operating scenarios were

not fully recognized in GIS software. Therefore, leaving the GIS environment

was necessary to use this data with other advanced modeling and planning

tools. While efforts to date have proven successful in allowing very basic

engineering analysis from a GIS, engineers have been reluctant to embrace

and utilize this technology.

Part of the reason for this reluctance can be attributed to the way many

GIS software treat data elements. For example, a water distribution system

that serves 150,000 people may have a GIS that contains anywhere from

100,000 to 250,000 separate pipe segments. From an engineering perspective,

this many pipe segments are not feasible for an accurate and manageable

hydraulic model. Presuming that a GIS were able to successfully model

that many elements, engineers will not want the task of evaluating the

voluminous amount of data generated from such an extensive hydraulic simulation.

Another reason for the hesitation to use a GIS software for network analysis

lies in the difficult command structures of many GIS software packages.

Engineers familiar with CAD based solutions may not find a GIS network

modeling package as intuitive, and would thus resist a new format which

may not appear to bring much additional functionality. Still another reason

for this reluctance may be the speed of the analysis software. Engineers

are used to working with time and budget constraints that will not include

extra time to run a lengthy and time-consuming hydraulic simulation. One

final and extremely practical reason for not choosing a GIS-hydraulic

model package may be the cost of many GIS modeling solutions. Spending

upwards of $15,000 to create and run a model that is less robust and has

fewer features than a $6,000 solution may prove difficult to justify,

especially for most users who are tied to a fixed budget.

It is for these reasons that engineers have opted to export the necessary

data from a GIS into a third party software application designed specifically

for the engineering analysis of a water distribution system. Therefore,

the GIS exporting process has become an accepted task among engineers

and has raised some common issues among practicing modelers.

Duplication of Data

One potential problem with exporting data outside of

a GIS and into a third party software application for engineering analysis

is the fact that a duplication of data may be created. Once this occurs

it becomes very difficult to ensure integrity between the two data sets

in the future (one data set being from the GIS, the other being from the

hydraulic model). This occurs because engineering models take on a life

of their own outside of a GIS3. Engineers spend hours tailoring the model

to match existing field conditions. Pumps, pressure reducing valves, storage

reservoirs, wells, closed pipes, etc. are all addressed by the engineer

in the hydraulic modeling software that would otherwise be disregarded

by the GIS manager. The engineer also goes to great lengths to ensure

data integrity within the model for the purpose of running a hydraulic

simulation. Pressure zone boundaries are delineated, demand area polygons

are created and point loads are determined. All of these activities bring

about the modification and adjustment of existing facilities as well as

the creation of new facilities, further complicating the task of taking

modeling data back to the GIS.

Finding Errors

While duplication of data is a potential risk when

creating an engineering model from a GIS, a recognized advantage is finding

errors in GIS graphic and non-graphic data sets. When GIS mapping began,

the first step for a city/utility was to decide how to best go about creating

the data and which department would oversee and supervise this process.

Many cities had decided to outsource data creation and then assigned an

internal Information Systems (IS) division to review the contract scope

and continue data management upon project completion. Due to outsourcing,

many cities received facility data sets that were not thoroughly inspected

for data accuracy. The engineering and operations departments, not realizing

the future impact of these outsourcing contracts, were not included in

the data creation process. Because of the combination of outsourcing and

IS oversight (not being aware of data needed by the engineer), preliminary

data integrity of a hydraulic system which is built directly from the

GIS may be questionable. While many cities believe they possess a highly

accurate GIS, it is only until the engineering department, in collaboration

with the operations department, utilizes GIS data for the sake of creating

a water master plan that the GIS inaccuracies are discovered. It is at

the time of a model creation for a system-wide master plan that issues

regarding pipe diameters, materials, location, connectivity, etc. are

thoroughly reviewed and inspected. What many find is that the GIS data

set consists of errors that require further investigation and correction.

Many master plans are delayed while GIS data discrepancies are adjusted

to match field conditions.

While these errors may be addressed and resolved in the hydraulic model,

little is done to ensure that all corrections are taken back to the GIS.

In many instances, once a hydraulic model is created for a master plan,

the model becomes more accurate than the original GIS data used in its

creation. A solution to this problem can now be realized using an integrated

geospatial network modeling methodology.

A New Geospatial Solution

The proposed geospatial software, H2OMAP

Utility Suite, approaches water modeling from a GIS-centric point of view

for spatial database management and analysis and works to avoid the duplication

effort involved in the creation of a hydraulic network model. Built entirely

with Esri MapObjects technology, the software uses the Shapefile (an industry

standard GIS format) as its native data format. Therefore, as pipes and

nodes are created, these data elements are also stored externally to the

program as Shapefiles, ready to be viewed and edited by any third party

GIS application. This integrated approach introduces a completely new

perspective to the application of GIS standards with network modeling.

It is further developed to host in a unifying framework the variety of

processes required for constructing, calibrating, and optimizing water

distribution network models. The integrated system combines the ability

to accurately build network topology, prepare requisite data, conceive

and evaluate multiple scenarios, execute optimization runs, and provide

both hardcopy reporting and graphical output display for evaluating and

presenting results.

The ability to make maximum use of all available data, from any department

or source, allows the utility to manage their infrastructure systems more

effectively. Since each department in an organization can control its

own data while giving other departments easy access to its most current

and accurate information, data is shared rather than duplicated and thus,

saving time and money across the organization. The following example is

provided to demonstrate the system's ability to reduce user errors and

facilitate network model creation.

Sample Project

A city has decided to undertake a water system master

plan. Using the city GIS water coverage, the GIS department assigns a

unique value (or ID) to each water facility in the GIS. The data is then

saved as a Shapefile and imported into the software. The engineer then

works on the hydraulic model, assigning pump curves to pumps, settings

to control valves, etc. In the process, the engineer establishes connectivity

and assigns facilities to their appropriate pressure zone. The engineer

proceeds to work on the hydraulic model, rectifying problem areas during

model construction. Since the data is automatically stored as Shapefiles,

the GIS manager views the modeling data in a GIS program to update changes

made by the engineer. This GIS update occurs directly without an importing

process, which would otherwise disrupt the modeler's task of building

the hydraulic model. The GIS manager may also opt to replace existing

facilities data stored in the GIS with those from the hydraulic model,

as the model data is now more accurate and contain additional data values

not stored in the GIS.

Because data sets are stored as Shapefiles, anyone in the organization

can view the hydraulic model outside of the model. Pipes, valves, tanks,

etc. can be added as views to ArcView or as layers in AutoCAD or Microstation.

Pressure contours from a hydraulic analysis and annotation layers for

labeling the hydraulic network are also stored as Shapefiles and can be

viewed at any time in any software package that supports the Esri Shapefile

format. The functionality of the proposed software allows engineers to

analyze distribution systems and GIS departments to integrate model data

in a smooth and seamless fashion.

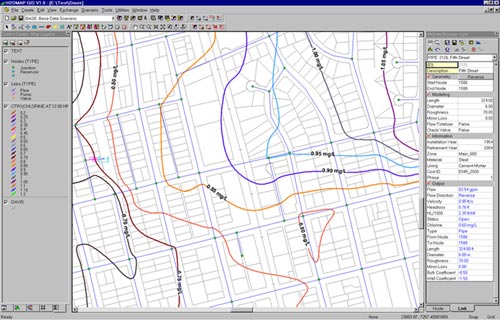

Advanced Functionality

The proposed integrated approach offers a full-featured

hydraulic analysis software solution for performing a wide range of essential

modeling tasks. Water utilities can use it for pump scheduling, developing

various planning scenarios, analyzing system flows and pressures, performing

water quality analyses, assessing fire flow capabilities, planning unidirectional

flushing programs, creating pressure contours, and monitoring SCADA operations.

The graphical interface is built with object-component technology to provide

a powerful and practical GIS platform for water utility solutions. As

a stand-alone program, it combines spatial analysis tools and mapping

functions with sophisticated and accurate network analysis capabilities.

GIS or CAD layers can be added to the program as background reference.

A small sample of files which can be directly imported include ArcInfo

coverages, Shapefiles, ArcSDE layers, Geodatabases, MIF/MID files, as

well as AutoCAD and Microstation drawings (DXF, DWG, and DGN).

The open-architecture framework allows fluent and flexible management

and distribution of geospatial data while facilitating the exchange of

critical modeling information with other applications and enterprise systems.

Immediate data storage and access in the Shapefile format puts the model

at the center of all enterprise solutions. Water utilities can develop

informed GIS solutions to help them increase engineering productivity,

exceed drinking water quality standards, optimize system operations and

capital improvement programs, and improve community and client relations.

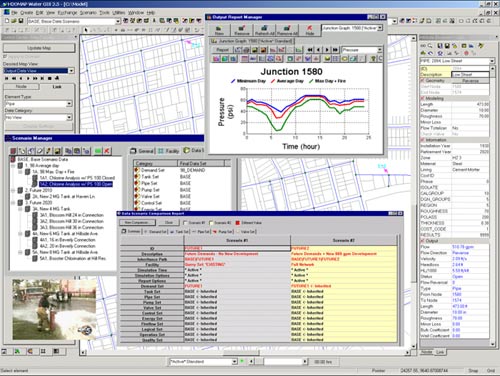

Multi-level Inheritance Scenario Management

A scenario manager allows modeling of multiple and

varied demand loading and operating conditions while benefiting from a

multi-leveled inheritance among planning scenarios. Every change made

to a "parent" scenario can be reflected through the entire set

of "child" scenarios for automatic acceptance of particular

data sets. With minimal effort, the hydraulic modeler can simulate skeletonized

systems, proposed facilities, and operational schemes to evaluate base

transmission pipe combinations, system behavior under varying demands,

and cost-saving operational procedures. Such capabilities allow the modeler

to alternate between scenarios, merge models of any size, and compare

results instantly to clearly illustrate optimal system performance under

any given network scenario and planning horizon.

Automated Network Model Reduction (Skeletonization)

Interfacing with GIS applications is a very reliable

and efficient method of developing hydraulic network models. However,

because GIS facilities are typically created for Automated Mapping/Facilities

Management (AM/FM) applications (e.g., water distribution system maintenance

and management), this format is generally not suitable for construction

of hydraulic network models. Common data format problems encountered by

practicing modelers who import to the network model are the inclusion

of hydrants, line valves, tees or crosses from the GIS.

A geospatial approach greatly simplifies and reduces large GIS models

to a manageable size ready for hydraulic analysis. It expeditiously processes

detailed GIS data, efficiently constructs reliable water system network

models using three automated data segmentation applications: data reduction

(Reduce), skeletonization (Skeletonize), and trimming (Trim) applications

(or RST applications), and re-allocate nodal demands.

Data reduction application is the ability to remove excessive pipe segmentation

caused by valves, fire hydrants or other data capture processes, by dissolving

interior nodes on pipe reaches and combining the associated pipe segments

into single pipes. For example, merging all series pipes of common diameter,

material, roughness coefficient and age. Data skeletonization application

refers to the capability of removing all pipes with diameters less than

a specified value (e.g., removing all 8 in and smaller pipes). The data

trimming application is the ability to remove short pipe segments leading

to dead ends such as service laterals and hydrant leads.

These network segmentation capabilities can be used effectively to screen

and accurately convert GIS data into a more practical and manageable hydraulic

model.

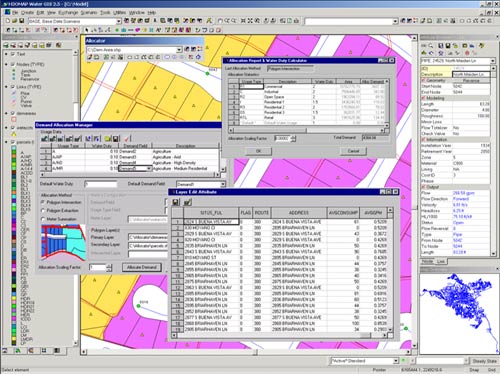

Demand Generation

Determining consumption and the spatial distribution

of consumption throughout the network model is a key element of modeling.

Network models are loaded with existing and future demands, depending

on the type of analysis performed. All sources, distribution pipelines

and available storage within the system are supporting elements that provide

service to meet these system demands. The variation of demand during the

course of a day must also be accounted for during an extended period simulation

(EPS). For static analyses, total system demand for various modeling conditions,

such as average day, maximum day, peak hour, etc., is spatially distributed

as a set of individual demand values allocated to selected junction nodes.

For extended time period (EPS) analyses (e.g., water quality), additional

temporal characteristics, typically represented by their respective diurnal

variations (hydrographs), are also required. Generally, the spatial demand

levels are first estimated for all junction nodes. The temporal effects

are then adjusted based on individual consumption categories.

Six accurate and fully automated methods can be used for processing geometric

polygons to accurately compute and load network models based on demand

type, location, and variation. These are:

1. Geocoded meter billing data (meter consumption database)

2. Shortest distance to junction

3. Shortest distance to pipe

4. Polygon Processing - spatial intersection of multiple polygon layers

5. Polygon Processing - spatial summation of consumption category area

polygons

6. Large users as individual point loads

The first method makes use of GIS layers to automatically geocode consumption.

The demand at each junction node is determined by identifying and summing

all the customers/meters within its associated service area polygon. In

the second method, each meter is assigned to the nearest junction while

the third method assigns each meter to the nearest pipe. In the fourth

method, demands are automatically calculated based upon a direct spatial

intersection between demand categorization polygons (e.g., land use polygons,

population polygons, pressure zone polygons, TAZ polygons, census tract

polygons, meter route polygons, and others) and the demand node area coverage

polygons (service area polygons). In the fifth method, nodal demands are

calculated by summing the individually assigned consumption category polygons.

In the last method, consumption levels for major users such as major industries,

schools, parks, golf courses, hospitals, etc. are identified directly

from their billing records and their demands are automatically assigned

as individual point loads at their respective junction nodes.

These comprehensive capabilities will allow water engineers to effectively

utilize their engineering knowledge and experience and leverage existing

GIS data investments to strategically define/forecast their network demand

distribution for various planning horizons in their master planning effort.

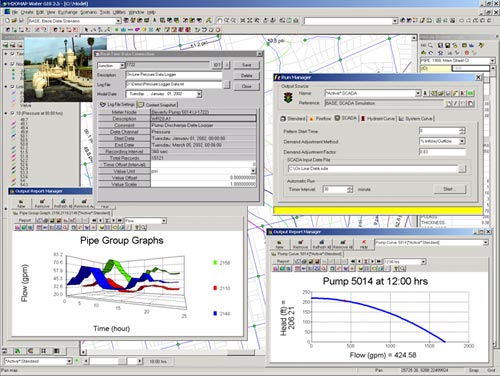

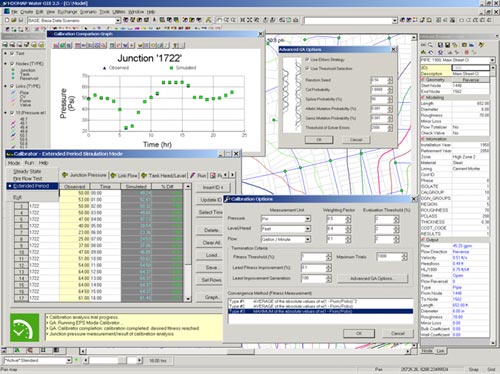

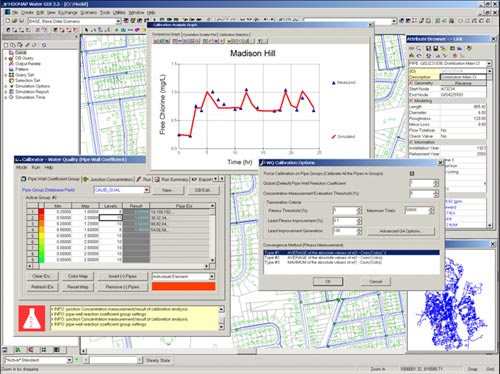

Automated Network Model Calibration

After a network model is properly constructed, it must

be calibrated to the physical system so that model predictions can be

interpreted with confidence5-6. Calibration entails adjusting certain

model parameters, usually the aggregate pipe roughness coefficients, until

the model results coincide with observed field conditions. The field conditions

most commonly used in network calibration correspond to the pressure readings

obtained from fire flow tests or from on-line SCADA systems. The price

for neglecting network calibration is basing decisions on a model that

may be seriously in error.

Typically, engineers will attempt to calibrate their network models using

a tedious and inexact trial-and-error process in which the model input

parameters (typically pipe roughness coefficients) are adjusted until

computed and field observations are within reasonable agreement. However,

since there is a vast number of possible combinations of parameter values

that need to be considered, the trial-and-error evaluation of all options

is unlikely to be practically feasible or manageable, and even knowledgeable

modelers often fail to obtain good results. As a result, network model

calibration has generally been neglected or done haphazardly.

In order to improve the reliability of hydraulic network models as well

as eliminate the need for trial-and-error calibration methods, the network

model calibration problem is cast as an optimization problem. It is then

solved using an improved variation of the Genetic Algorithm optimization

technology7-8 coupled with advanced elitist and global search control

strategies to significantly enhance accuracy and convergence. The calibration

model considers any combination of field pressure, tank level, flow and

water quality measurements, quickly determining pipe status and roughness

coefficient, pump and valve status, demand distribution and water quality

parameters to best reflect what is actually occurring in the system. It

offers comprehensive micro-level water distribution model calibration

capabilities - considering any time frame of calibration condition (e.g.,

maximum hour), an unlimited number of calibration scenarios (e.g., time-disjoint

fire flow test conditions), and complete extended period simulation calibrations

(e.g., on-line SCADA readings). Calibration results are then stored in

the database and accessed by the software's object-oriented interface

for graphical reporting and display.

Optimal Sampling Design

The credibility and efficacy of a calibrated network

model can only be as good as the data with which it was calibrated. While

field sampling programs are essential for model calibration, poorly defined

sampling designs may lead to calibrated roughness coefficients that are

not reasonable. Since only a limited number of measurements are normally

available due to resource constraints, the number and location of calibration

tests must be chosen to provide maximum information on the condition of

the system. If these locations are less than optimal, the data collected

may yield insufficient information for an accurate calibration and, thus,

would defeat the purpose of the calibration process.

Sampling design is currently performed by subjective judgement, thus depending

heavily on the experience of the modeler. In order to optimize the quality

of sampling designs for model calibration, the sampling design problem

is formulated as a dual-level combinatorial optimization problem and solved

using Genetic Algorithms. The dual-objective function is to determine

the minimum number of sampling locations (junction nodes) with pressures

that are collectively the most sensitive to changes in pipe roughness

values and also provide the most topological coverage of the network.

This ensures identifying the minimum set of junction nodes which stresses

the greatest percentage of the system and that are the most uniformly

spread so that pipe roughness values can be accurately inferred.

Considerable flexibility is allowed when screening sampling location results.

Because the optimization algorithm searches the solution space from a

population of points, and not just from a single point, alternative sampling

locations of the same quality, can be used and compared if additional

constraints are imposed, such as a location of an inaccessible or leaking

hydrant. The optimal sampling sites are then stored in the database and

conveyed back to the decision-support system interface for graphical query

and display.

Network Design and Rehabilitation

Cost-effective design and rehabilitation of water supply

and distribution systems is a problem of great importance in engineering

practice. Water utilities have been using network models to assist them

in planning their system rehabilitation and designing new systems. New

system design (or expansion to existing systems) is required to cope with

sustained growth while rehabilitation (or upgrading) of an existing system

is required to maintain adequate levels of service.

The network design and rehabilitation problem is cast as an optimization

problem and solved using Genetic Algorithms. It consists of determining

the optimal rehabilitation alternatives and pipe sizes for selected pipes

in the network that produce the minimum overall cost for a given set of

demand loading and operating conditions while satisfying the hydraulic

operational requirements of the system. The decision variables include

any selected combination of rehabilitation and design options such as

cleaning or cleaning and lining of existing pipes, pipe expansion, and/or

installing new pipes that can either parallel or replace existing pipes.

Cost data is specified for each option and for a range of pipe sizes.

This data will vary with pipe material and geographical location. System

operational constraints include minimum and maximum pressures at nodes,

and minimum and maximum velocity and hydraulic gradient requirements for

pipes. The results of an optimization run are then stored in the database

and can be displayed in both tabular and dynamic color graphic forms.

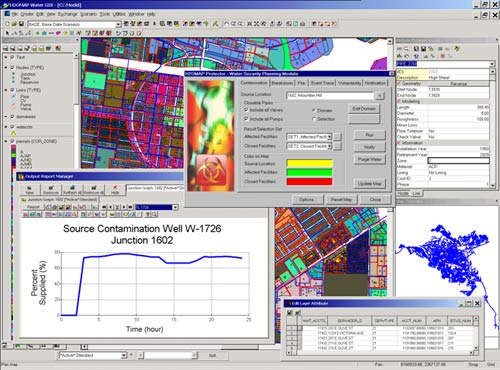

Water Security Planning and Vulnerability Assessment

Ensuring the provision of acceptable levels of reliability

in water distribution systems and reducing their vulnerability to natural

disasters and emergencies is a problem of great importance for water utilities

worldwide.

In order to improve the safety and security of drinking water distribution

systems, the software delivers an array of cutting edge water security

planning and vulnerability assessment tools. It allows water utilities

to model the propagation and concentration of naturally disseminated,

accidentally released, or intentionally introduced contaminants and chemical

constituents throughout water distribution systems; assess the effects

of water treatment on the contaminant; and evaluate the potential impact

of unforeseen facility breakdown (e.g., significant structural damage

and/or operational disruption). It enables users to locate all areas affected

by contamination; calculate population at risk and report customer notification

information; and identify the appropriate valves to close to isolate a

contamination event. Finally, it helps water utilities track contaminants

to the originating source; compute required purging water volume; develop

efficient flushing strategies; determine the resulting impact on fire-fighting

capabilities; and prepare data for eventual prosecution.

These capabilities will greatly assist water utilities in reducing their

infrastructure vulnerability and enhancing their ability to prepare for

and respond to natural disasters and emergencies. The software can be

effectively used to identify viable solutions before an incident or disaster

occurs, or to assist in responding should it occur9.

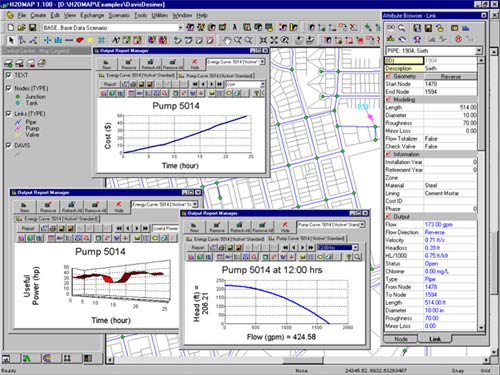

Pump Scheduling

Energy costs generally constitute the largest expenditure for nearly all

water utilities worldwide and can consume 65 percent of a water utility's

annual operating budget. One of the greatest potential areas for energy

cost-savings is the scheduling of daily pump operations.

Energy-saving measures in water supply and distribution systems can be

realized in many ways from field testing and proper maintenance of equipment

to the use of optimal computer control. Energy usage can be reduced by

decreasing the volume of water pumps (e.g., adjusting pressure zone boundaries),

the head against which it is pumped (e.g., optimizing tank water level

range), or the price of energy (e.g., avoid peak hour pumping and make

effective use of storage tanks such as filling them during off-peak periods

and draining them during peak periods), and increasing the efficiency

of pumps (e.g., ensuring that pumps are operating near their best efficiency

point). Water utilities can further reduce energy costs by implementing

on-line telemetry and control systems (SCADA) and by managing their energy

consumption more effectively using optimized scheduling of daily pump

operations.

The pump scheduling problem is cast as an optimization problem and solved

using Genetic Algorithms. The optimization problem consists of determining

the least-cost pump operation policy that will best meet target hydraulic

performance requirements. The operation policy for a pump station represents

a set of temporal rules or guidelines (pump operating times) that indicate

when a particular pump or group of pumps should be turned on and off over

a specified period of time (typically 24 hours). Th optimal operation

policy is defined as that schedule of pump operations that will result

in the lowest total operating cost for a given set of boundary conditions

and system constraints. System constraints prescribe lower and upper limits

on nodal pressures, pipe velocities, and storage tank levels, and final

tank volumes at the end of a specified time period (normally 24 hours)

to ensure hydraulic periodicity. The resulting optimal control rules for

each pump in the system are then stored in the database and passed back

to the decision-support system interface for graphical results presentation.

Results Presentation

The use of powerful GIS thematic mapping functionality

makes it easy to turn dry database information into stunningly colorful,

fully dimensional visualizations and to present analysis results in map

form. Users can generate accurate, and smooth contours for any variable

including elevation, pressure, hydraulic grade line, demand, water age,

chlorine concentration, and more, directly on the map - even overlay multiple

contours on a single drawing. Draw on a range of other sophisticated graphical

presentation tools, including color-coded mapping, dynamic annotation/labeling,

graphing, profiling, customizable tabular reporting, and vivid VCR-style

animation to produce truly compelling results. These graphical capabilities

are critical to better communicate and understand problem areas and system

deficiencies and to present remedial engineering solutions at community

information sessions or council meetings.

Conclusions

Water utility engineers are discovering a wide variety

of uses for GIS technology. In particular, GIS information is critical

to water distribution system planning and analysis. A new geospatial software,

H2OMAP Utility Suite, has been presented as a decision support

system to provide a GIS-based solution for water distribution system modeling

and management. Built entirely with Esri MapObjects technology, the software

system seamlessly integrates sophisticated GIS features and functionalities

with a hydraulic network simulator and optimization theory allowing accurate

network model construction and providing a reliable and effective means

for decision makers to quickly assess and address the implications of

alternative design, rehabilitation and operational changes on system performance.

Through the exploitation of GIS graphical data visualization capabilities,

potential system deficiencies can be quickly identified where improvements

are required. The resulting GIS-based software allows a wide range of

potential network improvement and enhancement alternatives to be modeled,

analyzed, contrasted, and evaluated, providing water utility managers

with the ability to readily optimize their capital improvement programs.

It also equips water utilities with expanded power and flexibility in

estimating the consequences of a terrorist attack or a crisis event on

their drinking water supply infrastructure, and in formulating and evaluating

sound emergency response, recovery, remediation and operations plans and

security upgrades. Finally, the software makes it easy for any utility

to work seamlessly across platforms and to manage water systems in a single

environment.

References

- H2OMAP Water - Users Guide. MWH Soft,

Inc. 300 North Lake Avenue, Suite 1200, Pasadena, CA 91101.

- H2OMAP Skeletonizer - Users Guide.

MWH Soft, Inc, 300 North Lake Avenue, Suite 1200, Pasadena, CA 91101.

- Miles, S.B and Ho, C.L. (1999). "Applications

and issues of GIS as a tool for civil engineering modeling." Journal

of Computing in Civil Engineering ASCE, Vol. 13, No. 3, pp. 144-152.

- H2OMAP Demand Allocator - Users Guide.

MWH Soft, Inc, 300 North Lake Avenue, Suite 1200, Pasadena, CA 91101.

- Boulos, P.F. and Ormsbee, L.E. (1991). "Explicit

network calibration for multiple loading conditions." Journal of

Civil Engineering Systems, Vol. 8, pp. 153-159.

- H2OMAP Calibrator - Users Guide.

MWH Soft, Inc, 300 North Lake Avenue, Suite 1200, Pasadena, CA 91101.

- Boulos, P.F. et al. (2001). "Using genetic

algorithms for water distribution system optimization." In Proceedings

of the ASCE Environmental and Water Resources Institute's (EWRI's) World

Water & Environmental Resource Congress, May 20-24, Orlando, FL.

- Boulos, P.F. et al. (2001). "Optimal operation

of water distribution systems using genetic algorithms." In Proceedings

of the AWWA Distribution System Symposium, September 23-26, San Diego,

CA.

- H2OMAP Protector - Users Guide.

MWH Soft, Inc, 300 North Lake Avenue, Suite 1200, Pasadena, CA 91101.

|