To effectively manage a hydrant servicing system, database systems may be integrated with GIS to create a graphical interface that reduces errors and improves overall water system confidence

. The Kissimmee Fire Department is a 70-member department with 63 combat

personnel that provides fire and emergency medical services to a population of

approximately 50,000 residents, and a large transient tourist population. Our

proximity to Walt Disney World has created a rapidly growing environment with

daily challenges unique to our area. The City of Kissimmee made a commitment

several years ago to develop an excellent fire rating to attract businesses and

residents. As part of this effort, we have maintained a rating of ISO 2 on a

scale of 10, with 10 being the lowest rating. This is a stringent rating system

and we fall into less than 1% of the fire departments in the nation. The

Insurance Services Organization, which evaluates fire departments, develops the

ISO rating, and the rating is reflected in lower property insurance

rates.

Forty percent of the scoring by ISO is related to the water system in

the community. While we do not install and maintain the water system, we are

tasked with maintenance and yearly testing of the hydrants for function and

readiness.

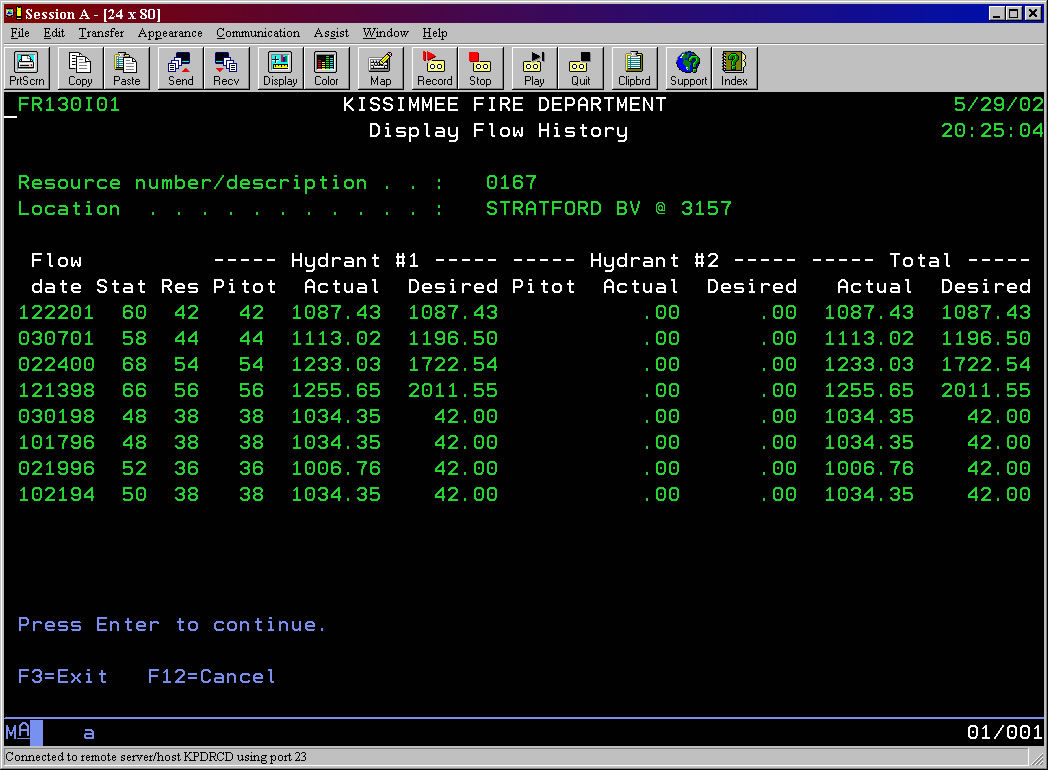

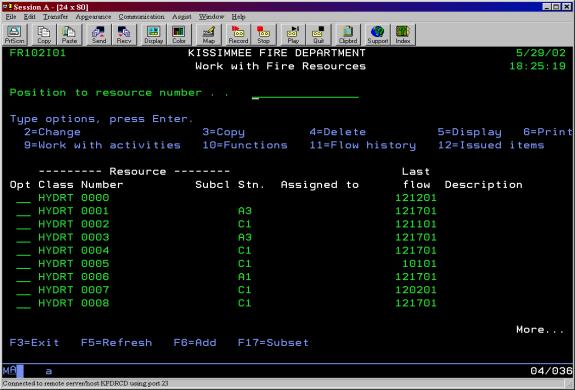

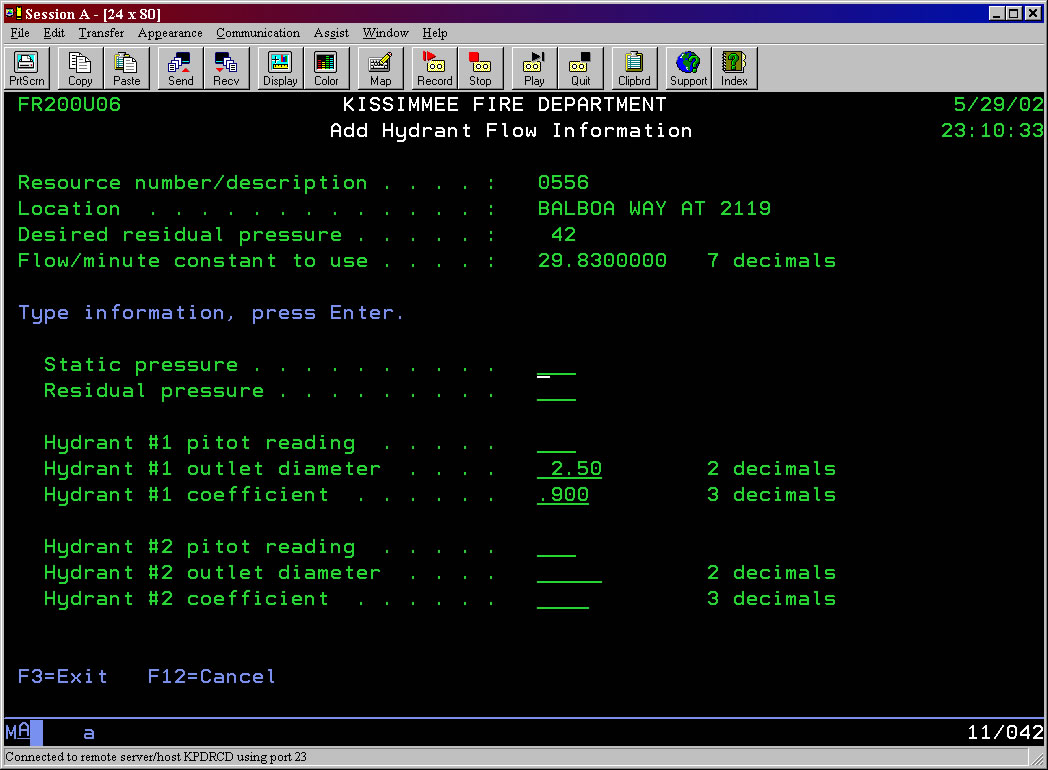

During our yearly process of testing, we must flow each of the

1600 hydrants in the City, record static pressure, flow pressure, and determine

actual flow. This is usually accomplished with on-duty crews in the normal

course of the shift. For years, our data has been stored in an HTE A/S 400

system. This system is very effective for data storage, but difficult for

visualizing areas of flow problems and is limited in hydrant location

description.

While this had been a vexing problem for a long time, resulting in confusing

and possibly missing data, we were guided by the GIS team within the City, Tony

Curtis and Matt Cieri, to consider a new and more effective means of integrating

data with a visual representation of the hydrant information. We had never seen

ArcView, and were excited about the idea. Tony and Matt were excited since they

did not have to do the work. However, our lack of knowledge was overcome by a

strong desire to create a usable system that would serve our firefighters and

citizens effectively as well as satisfy the needs of monitoring organizations

like ISO.

Under the tutelage of the GIS department, we began a long and

sometimes frustrating, but successful, journey that we hope can benefit other

fire departments facing this problem.

The first step in developing a map

based hydrant database, and without doubt the most important, is to identify

your in-place knowledge base and resources. Having a limited idea of what GIS

was, what it could do, and how to use it, I turned to our GIS department. Do not

be afraid to plead ignorance on any point. Sometimes a firefighter is speaking

of one thing, but a GIS specialist is interpreting it in a very different way.

Do not be afraid to lean on their expertise, but pay attention and look for

common ground. Try to learn how they look at problems so you may frame issues in

a more meaningful manner. Once you learn about shapefiles, dig deep and search

for data that may match your needs.

Our GIS department had extensive

shapefiles of roads, buildings, and water bodies that assisted greatly in giving

us the initial idea of where we needed to add hydrants and how it would

appear.

Simply put, a shapefile, (for this purpose), is a set of points with

associated tabular data containing information about a dot on a map. This data

can be a written description of location, flow pressures, or unique

identification numbers. Once created, the dot on the map can be easily projected

onto street maps for easy reference.

Our Water Resources Department had a very dated shapefile of hydrant

locations, with no useful tabular data, but it created a good starting point. If

there is no existing shapefile available, consider a field collection system

with ArcPad on a handheld, and plot your hydrants accurately. Start with a basic

street map, and drive the areas, mark your hydrants locations, and add

identifying data as you go. If you have hydrant data existing in some form, you

add it to the points.

Our existing hydrant data was mostly on green bar

printouts, with 17 letters of descriptive location data. By examining the

ArcView shapefiles, each hydrant was identified and a node number added to the

table on the map. Since the database in the A/S 400 was created 10 or 12 years

ago, there were many descriptions that were completely inaccurate or missing

entirely. Add approximately 600 new hydrants in that time frame, and the task

was even more daunting. A new field was created in the A/S 400 to add a

distinctive node number from the shapefile for joining the information later.

Any type of database can be used to store your hydrant data. Whether it is

Microsoft Excel or Access, or any other spreadsheet format, it can easily be

attached to an ArcView or ArcMap shapefile to correlate data. The most important

thing to remember is to be sure you have unique identifiers that exist in both

the map data and the database. Without this link your records will be

meaningless and useless, and it will frustrate your efforts.

Once we were

relatively comfortable with the correlation of the existing points and hydrants,

the IT department assisted by downloading the A/S 400 data in a text file,

ensuring that the node number was included. Then, the data was joined, and the

real work began.

Joining data in ArcView or ArcMap allows the program to

utilize any of the tabular data for labeling on the maps, whether the hydrant

number, location description, or flow pressures. The easiest way to explain the

process is to imagine two paired columns of numbers, one random and the other

ordered. Then, create another set of columns, again with one set random, the

other ordered. The ordered numbers are the common ground that would allow the

random numbers to relate. Any point in a map may be given a unique identifier,

whether it is the GPS location or the hydrant number from your data. The

important issue is to be sure the database and the shapefile have common

integers so they may be linked.

Random checks were performed on over 50% of

the projected map data. Labeling each hydrant with the initial joined resource

number, then comparing the label to the stored data in the A/S 400 accomplished

this. We set up a workstation with both ArcMap and the A/S 400 interface running

side by side, and quickly checked the points. If a discrepancy was noted, it

could be readily corrected. Some of the hydrant points were moved from one side

of the road to the other, occasionally a point was moved a mile. But with each

change, the data became more accurate.

As we further cleaned up the data and confirmed the locations, our annual testing period was approaching. Since our confidence level was not 100%, it became imperative that the crews testing the hydrants would be our quality assurance. At the beginning of the testing period, we used ArcMap to create 11 x 17 maps of each crew’s area of responsibility, appropriately labeled. The large format gave them easy to read labels, and allowed for additions or corrections in the field. The crews could enter test data in either of two methods; writing the pressures on the map next to the hydrant for later entry, or directly into our A/S 400 interface through the mobile computers on the vehicles. Both entry methods were effective, but the field entry was most well received and less time consuming.

At the end of the three-month testing period, IT ran another report for data containing hydrant resource numbers, test date, and flow pressure. This information was then joined to existing data in ArcMap, and a graphical representation was created. Using the flow pressure results, each hydrant was assigned a color within a class range. The ranges approximated gradients of up to 500 gallons per minute, 501 to 750 gpm, 751 to 1000 gpm, and 1001 gpm or above. The hydrant symbols were then displayed with brightly contrasting colors to help clarify areas of low flow, which are inherently dangerous and present inefficient water for structural firefighting.

For the first time in the Kissimmee Fire Department’s history, as the map

appeared on the screen, we were able to see problems and understand

relationships that had been difficult to perceive. Immediately, we identified

one water main that appeared to be partially closed and notified the Water

Resources department of the situation. An added benefit was not manually scan

reams of printouts to determine tested/untested areas. Within half an hour, we

can have the whole of the project on our desktop.

Each testing period will

now be prefaced with identification of new hydrants, and creation of the

now-familiar maps for the crews. Acceptance was good and they are able to see

and appreciate their hard work. This process will be refined each year and will

lead to insight and ideas for improved application of GIS for our everyday Fire

Department use.

As we marveled at the success, we realized more than simple

graphical display of hydrant data. We have learned about the wealth of useful

GIS information available, shared updated data, learned how to use the Esri

products, and most importantly, developed excellent working relationships within

our city government structure we had not had before. One important area of

impact has been the man-hour savings with a reduction of approximately 800

hours/year resulting from improved efficiency in locating hydrants and data

entry. Our Department is now confident of the locations of our hydrants,

accuracy of our data, and our ability to ensure protection for our

citizens.

We have also transferred our updated shapefile to the GIS

department for inclusion on our MDC map display interface for immediate

reference during emergencies and given the results to the Water Resources

Department for their use.

The main lessons learned are to actively mine your

resources for knowledge and assistance, don’t be afraid to try new methods, and

once you get past the initial bumps, share with everyone. The payoff will be

tremendous.